High-speed world-class fully automatic machine, TP-702B, TP-702BP

Main Features

Innovative world-class model Designed for general purpose applications

Reliable and Robust Strapping Head

Mercury Transit machines use the latest DC brushless motor technology to provide the highest level of accuracy and reliability on the market. All motors are German-made.

The strapping head has no belts, clutches or pulleys. It is designed with up-to-date technology with few moving parts. With 30% fewer parts, Mercury Transit machines require fewer adjustments, have fewer wear components, and require less maintenance. The simple design of Mercury Transit minimizes the maintenance cost

Electronic Tension Control

The operating control panel with LCD display is located on upper side of the machine for easy access. External adjustment of strap tension by the simple turn of a dial. Easy operation

Free Access to Strap Guides (patents registered)

Unblock the guides enabling free and quick access to the strap guides without the use of any tools. The most maintenance-friendly design.

Waist-High Quick Coil Change (patents registered)

Innovative waist-high coil change without access to the bottom of the machine. Quick release lock eliminates downtime to change the coil. Ergonomic and quick change design makes coil change simpler than ever.

Waist-High Auto Strap Feeding

Friendly design to feed the strap automatically from the upper side of the coil without the need to access to the bottom of the machine.

Hinged Top Plates

Opens wide for quick cleaning, inspection, and maintenance of strapping head, strap-feed and tensioning unit.

Auto Strap Ejector

Loop-eject clears unwanted strap automatically if the machine is accidentally operated without a package. Eliminates downtime.

Green Tech

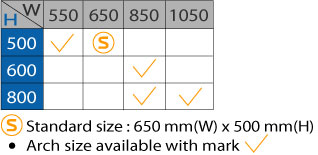

Arch Sizes

More Features

- Multiple strap function for single, double, continuous strapping or transit mode

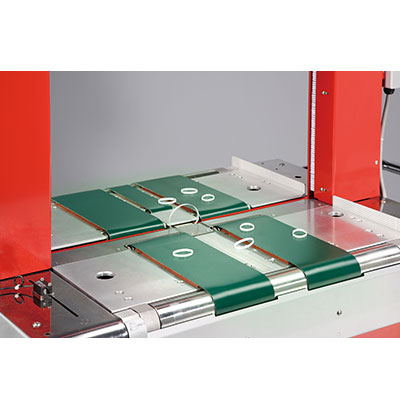

- Belt-driven table with variable conveyor speed between 10 and 60 meter/minute

- Up and down stream interlock with complete plug connection

- Easy bundle flow direction change

- Quick coil change

- Good to strap small package with minimum size 120 mm in width and 10 mm in height

- Sensor controlled heater assuring consistent and high joint efficiency

- Automatic end-strap detection and ejection

- Adjustable table height between 800 mm and 900 mm

Options

- Siemens PLC control

- Max. tension up to 45 kg (for 9mm)

- Lower adjustable table height (750 mm – 900 mm)

- Stainless Steel Frame (TP-702BS)

- Operator friendly low strap sensor (triple lamp)

- Energy saving transit with auto sleep mode

- Strapping in the centre of the bundle

- Extension belt-driven table of 200 mm on upstream and downstream side

- Lower adjustable table height (750 mm – 900 mm)

| Technical Data | |

|---|---|

| Strap Width | 5 mm, 6 mm, 9 mm or 12 mm |

| Strap Tension | 1-32 kg (for 5 mm, 6 mm, and 9 mm),1-45 kg (for 12 mm) |

| Speed Per Minute (60Hz) | Up to 40 packages per minute(Cycle speed up to 65 straps per minute) |

| Net Weight | 225 kg |

| Electrical Requirements | 110V, 220V, 230V 50/60Hz 1PH 220V, 380V, 400V 50/60Hz 3PH |